Benefits of Hot Isostatic Pressing (HIP) on Superalloy Castings

Superalloy Castings and Their Industrial Significance

Superalloy castings are high-performance materials engineered to withstand extreme conditions. Known for their exceptional strength, oxidation resistance, and thermal stability, superalloys are commonly used in high-stress industries like aerospace, power generation, oil and gas, and medical equipment manufacturing. These alloys comprise critical components such as turbine blades, combustion chambers, valves, and downhole tools, where failure is not an option.

Enhancing Superalloy Castings with Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a powerful post-processing technique that further enhances superalloy castings' performance and reliability. By applying high pressure and temperature in a controlled environment, HIP removes internal porosity, increases density, and improves mechanical properties. This blog explores how HIP works, its benefits to superalloy castings, and its significance in various high-demand applications.

Understanding Hot Isostatic Pressing (HIP)

What is HIP?

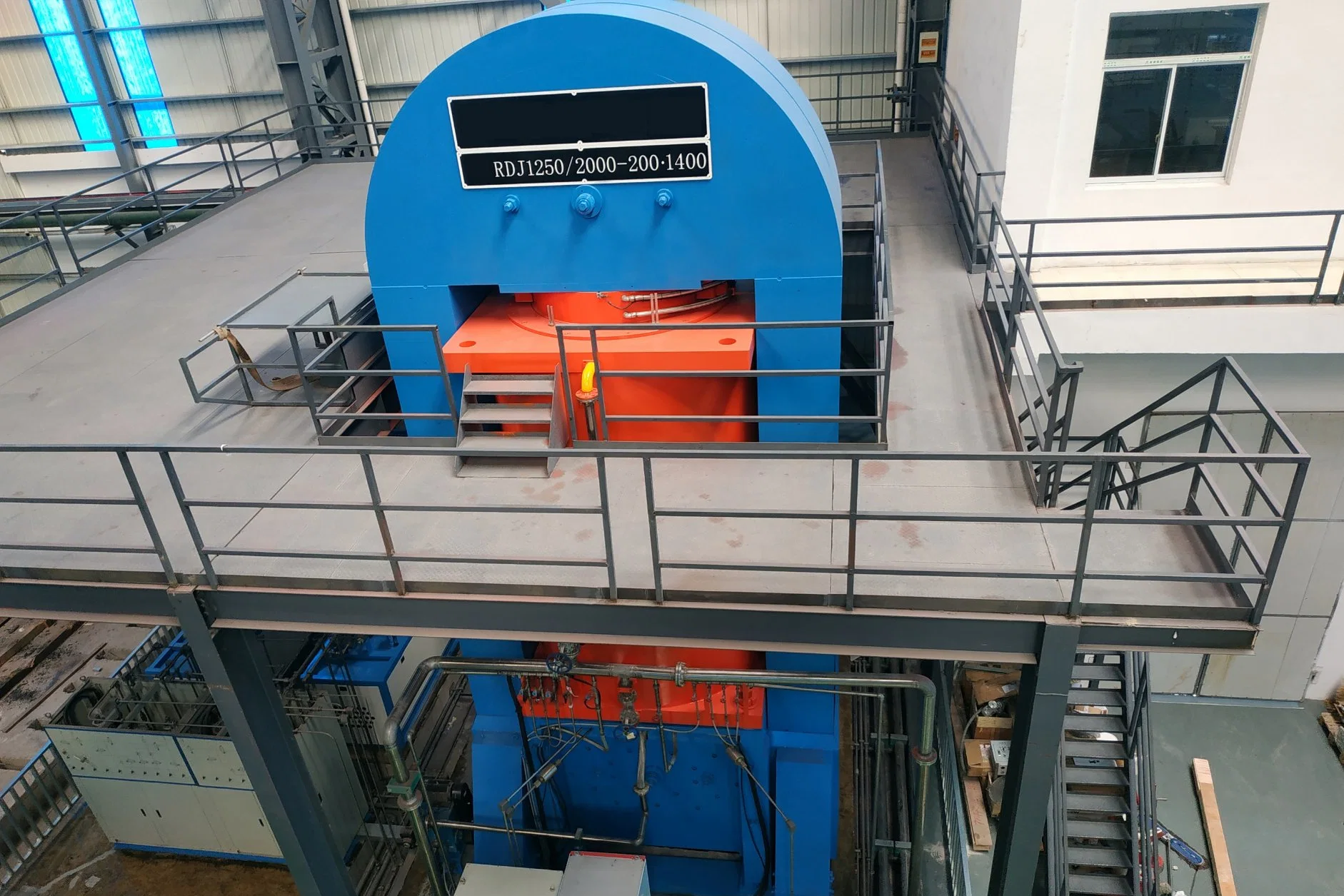

Hot Isostatic Pressing (HIP) is a post-processing method that combines high pressure and high temperature in a pressurized gas chamber (often argon) to densify materials and eliminate internal porosity. The process enhances the material's mechanical properties by creating a uniform, defect-free structure. HIP is widely used in producing superalloy castings due to its ability to improve the strength, toughness, and overall reliability of components.

How HIP Works

Loading the Casting: The casting is placed in a HIP chamber filled with an inert gas, typically argon.

Pressurization and Heating: The chamber is heated to a high temperature while applying isostatic pressure from all directions.

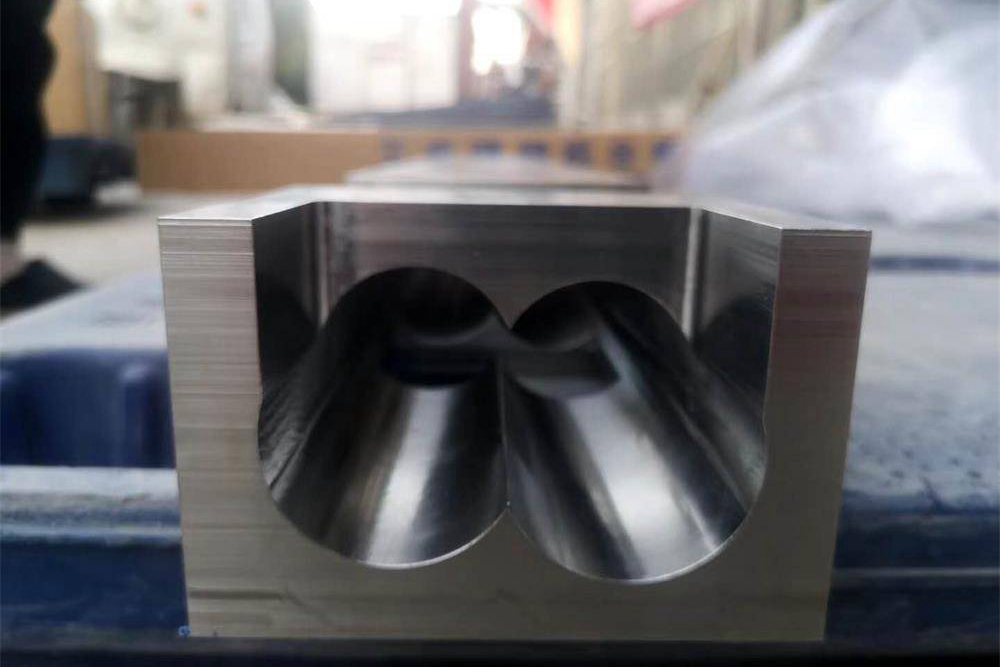

Densification: Under these conditions, any internal pores or voids within the casting are compressed and eliminated as the material undergoes plastic deformation to fill gaps.

Controlled Cooling: After the desired density and microstructure are achieved, the component is cooled in a controlled manner to stabilize its structure.

This step-by-step HIP process enhances superalloy castings' uniformity, density, and structural integrity, making them ideal for high-stress applications.

Why HIP is Essential for Superalloys

Due to their complex manufacturing processes, Superalloy castings often have internal porosity and non-uniform grain structures. Porosity and inclusions can act as weak points within the alloy, reducing its ability to withstand stress and increasing the risk of failure. HIP addresses these challenges by compressing and removing porosity, homogenizing the microstructure, and refining grain size. As a result, HIP-treated superalloys offer improved mechanical properties and long-lasting performance under demanding conditions.

How HIP Supports Specific Superalloy Applications

Aerospace Components

Superalloy components must endure high temperatures and stress in aerospace, particularly in jet engines and turbines. HIP-treated superalloys are used in turbine blades, combustion chambers, and structural components, where eliminating internal defects and achieving a uniform microstructure are crucial for reliable performance. The improved strength and creep resistance provided by HIP allows these components to withstand the extreme conditions encountered during flight, reducing the risk of in-flight failure.

Power Generation

Gas and steam turbines in power plants also utilize superalloys for their high-temperature and load-bearing capabilities. HIP-treated superalloys are used in turbine components subjected to constant stress and temperature fluctuations, as they provide superior resistance to thermal fatigue and oxidation. The use of HIP in power generation helps enhance the efficiency and longevity of turbines, lowering operational costs and improving energy output reliability.

Oil and Gas Industry

The oil and gas industry requires materials that resist corrosion, pressure, and extreme temperatures. HIP-treated superalloys are used in downhole tools, valves, pumps, and other equipment exposed to aggressive environments. The process increases corrosion resistance and mechanical strength, ensuring that components maintain integrity during drilling and extraction operations, where failure could be costly and dangerous.

Medical Implants and Industrial Applications

In the medical field, HIP-treated superalloys are used in high-purity, defect-free implants where reliability is critical. Industrial applications that involve heavy machinery, pumps, and valves also benefit from HIP, as the process produces components with consistent mechanical properties and resistance to wear. HIP ensures these parts perform safely and reliably, even under continuous stress.

Comparison of HIP to Other Post-Processing Techniques

HIP vs. Heat Treatment

While HIP and heat treatment improve mechanical properties, HIP specifically addresses internal porosity and densifies the material. In contrast, heat treatment modifies grain structure to relieve stress and enhance hardness. Heat treatment is often combined with HIP to achieve both densification and optimized mechanical properties in superalloys, particularly for applications requiring enhanced durability and life.

HIP vs. Welding and Surface Coating

Welding and surface coatings repair or protect the surface of superalloy components. However, HIP addresses internal defects and densifies the entire structure, ensuring consistent mechanical properties throughout the material. HIP can be used alongside these surface treatments to provide comprehensive protection and durability, especially with thermal barrier coatings that enhance performance in high-temperature applications.

HIP Combined with Other Processes

HIP is often used with machining, heat treatment, and coatings to create superalloy components that meet exacting standards. Combining HIP with other post-processing techniques enhances both internal and surface properties, producing components that can withstand high-stress environments and long-term use. This synergy of processes results in high-quality, defect-free components that excel in demanding sectors like aerospace and power generation.

What Superalloy Parts Need HIP

Superalloy parts that undergo Hot Isostatic Pressing (HIP) significantly benefit performance and durability. Some standard superalloy components treated with HIP include:

Vacuum Investment Castings: Used in aerospace and power generation, these castings benefit from HIP's ability to eliminate porosity and strengthen the alloy.

Single Crystal Castings: Critical in jet engines, HIP helps prevent grain boundary weaknesses in single crystal parts.

Equiaxed Crystal Castings: HIP refines the grain structure and eliminates defects, which is ideal for parts experiencing multi-directional stress.

Directional Castings: HIP enhances fatigue resistance and high-temperature performance in rotating machinery.

Special Alloy Castings: HIP optimizes the performance of unique alloys in demanding environments.

Powder Metallurgy Superalloy Parts: HIP removes voids common in powder metallurgy parts, resulting in a more robust, denser alloy.

Precision Forging Parts: HIP increases strength and consistency in forged superalloy components, which is critical for aerospace and power applications.

CNC Machined Superalloy Parts: HIP relieves stress and improves mechanical properties in machined parts.

3D Printed Superalloy Components: HIP densifies the printed structure, making it reliable for structural and high-performance applications.

FAQs on Benefits of Hot Isostatic Pressing (HIP) on Superalloy Castings

What specific properties does HIP improve in superalloy castings?

Can HIP be combined with other heat treatments to enhance superalloy performance?

How does HIP contribute to extending the service life of superalloy components?

Why is HIP more effective than other post-processing methods for porosity elimination?

What types of superalloy castings benefit most from HIP?