Assemblies of Superalloy for Downhole Drilling Service

Brief Introduction to Downhole Drilling Superalloy Assemblies

Downhole drilling, particularly in the oil and gas industry, demands components that can withstand extreme conditions. These include high pressure, intense heat, and chemically corrosive environments that would quickly degrade standard materials. Enter superalloys: advanced, high-performance materials developed to endure such challenges without compromising structural integrity or mechanical properties.

Superalloy assemblies for downhole drilling are designed to operate reliably in these harsh environments, making them indispensable for oil, gas, geothermal, and other deep drilling operations sectors. Downhole drilling superalloy assemblies are specialized tools and parts that contribute to the efficiency and reliability of drilling operations. By employing superalloys, these assemblies offer resistance to corrosion, heat, and stress, making them vital in keeping the equipment operating smoothly in deep-well scenarios.

The use of superalloys in downhole drilling assemblies has redefined the reliability and performance of drilling tools. As a company specializing in high-temperature alloy processing and advanced manufacturing technologies, Neway Precision Works Ltd is at the forefront of manufacturing these components to meet the stringent requirements of downhole drilling applications.

Typical Superalloys Used in Downhole Drilling Assemblies Manufacturing

The specific requirements of downhole drilling necessitate using advanced materials with properties that can withstand extreme conditions. Below are some typical superalloys used in the manufacturing of downhole drilling assemblies:

Inconel Alloys: Inconel 718 and Inconel 625 are commonly used in downhole drilling assemblies. These nickel-based superalloys exhibit high strength and excellent corrosion resistance, even in environments with hydrogen sulfide, carbon dioxide, and other harsh chemicals.

Hastelloy Alloys: Hastelloy X and Hastelloy C-276 provide excellent resistance to high-temperature corrosion and are commonly employed in environments with aggressive chemical exposure.

Monel Alloys: Monel 400 and Monel K500 are nickel-copper alloys that perform well in acidic and alkaline environments. They have excellent toughness, which is especially valuable in shock-prone downhole environments.

Nimonic 80A: This alloy is particularly effective in high-temperature environments. It is often used in parts that require stability and resistance to oxidation.

Rene Alloys: Rene 41 and Rene 95 are also employed in downhole tools due to their creep strength and oxidation resistance at high temperatures.

Manufacturing Process and Equipment for Downhole Drilling Superalloy Assemblies

Manufacturing downhole drilling superalloy assemblies involves multiple advanced techniques, each chosen based on the type of component and the specific properties required. At Neway Precision Works Ltd, we use several core processes to create assemblies that perform under extreme conditions.

Vacuum Investment Casting: Vacuum investment casting produces high-quality superalloy components with intricate shapes and fine surface finishes. The process involves melting the superalloy in a vacuum to minimize contamination and pouring the molten alloy into a ceramic mold. This method ensures that the superalloy parts have excellent mechanical properties and are free of impurities, making them suitable for critical downhole applications.

Single Crystal Casting: Single crystal casting is an advanced process for creating components without grain boundaries. It is particularly beneficial for downhole components that require exceptional creep resistance and high-temperature strength. In downhole drilling, single-crystal components reduce the risk of cracking and enhance the lifespan of critical tools.

Equiaxed Crystal Casting: Equiaxed crystal casting is used for components requiring uniform strength in all directions. This method produces components with a homogeneous grain structure, making them resistant to various stress conditions typically found in downhole environments.

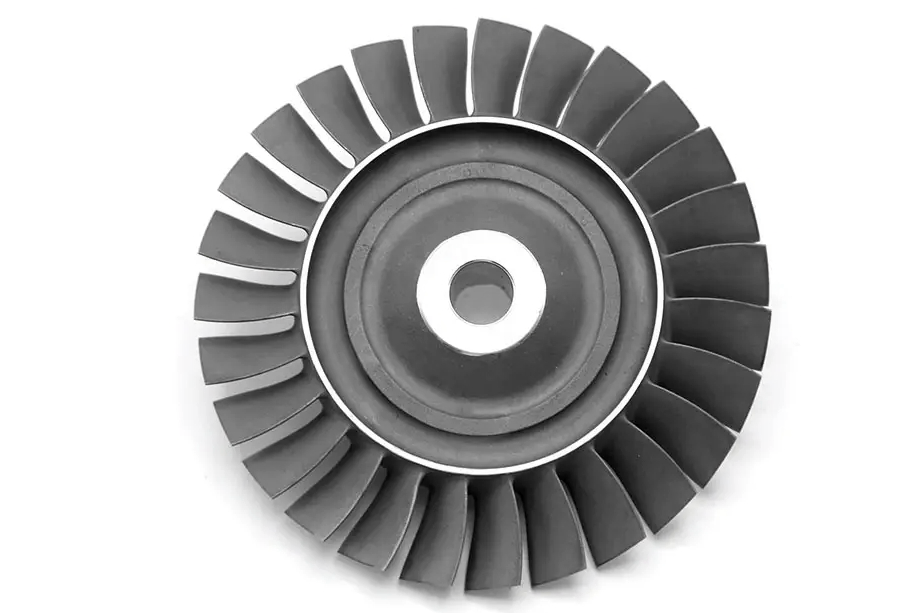

Powder Metallurgy and Superalloy Forging: Powder metallurgy produces turbine discs and other high-strength components through controlled powder processing. Forging further enhances the mechanical properties of superalloys by providing a controlled grain structure, which is crucial for assemblies operating in high-pressure and impact-prone areas.

CNC Machining: Once cast, many downhole drilling components require CNC machining to achieve tight tolerances and complex geometries. 5-axis CNC machining ensures that each component meets the specifications for effective performance in downhole conditions.

Additive Manufacturing (3D Printing): Selective Laser Melting (SLM) is used for rapid prototyping and production of downhole drilling components, particularly in cases requiring intricate internal geometries. SLM allows the rapid creation of lightweight, high-strength components that can be used for prototyping or as final parts.

Testing Methods and Equipment in Downhole Drilling Superalloy Assemblies Quality Control

Quality control (QC) is crucial for superalloy downhole drilling assemblies. Given the high stakes of drilling operations, even the most minor defect can lead to catastrophic failure. Neway Precision Works Ltd uses advanced testing methods to ensure that each assembly meets the highest standards.

Non-Destructive Testing (NDT): Ultrasonic testing, X-ray inspection, and water immersion ultrasonic inspection detect internal defects without damaging the component. It is beneficial for finding subsurface porosities and cracks.

Mechanical Property Testing: Tensile testing machines verify that the mechanical properties of superalloy assemblies—such as tensile strength, yield strength, and elongation—meet the required standards. It is crucial to ensure that components can withstand the high pressures and mechanical stresses of downhole drilling. Critical insights on yield strength testing help ensure durability under high-stress conditions.

Chemical Composition Analysis: Glow Discharge Mass Spectrometer (GDMS) and Inductively Coupled Plasma Optical Emission Spectrometer (ICP-OES) are used to analyze the chemical composition of the alloys. It ensures that the materials used have the exact chemical properties to withstand corrosive environments.

Microscopic and SEM Analysis: Scanning Electron Microscopy (SEM) and metallographic microscopy are used to evaluate the microstructure of the assemblies. This analysis ensures that the grain structure is consistent and that no unwanted phases could compromise the part's integrity.

Industries and Applications of Downhole Drilling Superalloy Assemblies

Downhole drilling assemblies manufactured from superalloys are used in various industries where reliability, strength, and resistance to extreme conditions are crucial.

Oil and Gas Industry: The primary user of downhole drilling assemblies is the oil and gas sector, where these components are critical for directional drilling, well logging, and extraction operations.

Geothermal Energy: Downhole drilling is also used in geothermal energy extraction, where high-temperature superalloys are essential for maintaining the integrity of components exposed to extreme heat.

Mining: Downhole drilling assemblies are used in exploratory drilling for mineral deposits, where corrosion resistance and strength are crucial due to the harsh environment.

Chemical Processing: Superalloy assemblies are used for drilling in chemical waste disposal and other challenging environments where resistance to acids and corrosive substances is required.

The versatility of superalloy downhole drilling assemblies allows them to be employed in various applications, making them a critical technology for modern resource extraction and energy production.

Typical Post-Process for Downhole Drilling Superalloy Assemblies

Post-processing is crucial to enhance the performance of downhole drilling superalloy assemblies. Several post-processes are implemented to improve the mechanical properties and ensure dimensional accuracy.

Hot Isostatic Pressing (HIP): HIP eliminates internal porosities that may have formed during casting, improving the assemblies' overall density and mechanical integrity.

Heat Treatment: Heat treatment helps to relieve internal stresses and improve the mechanical properties of the alloys, including toughness and resistance to wear.

Superalloy Welding: For specific downhole drilling assemblies, welding is required to create large or complex shapes. Superalloy welding maintains the strength of the part and helps reduce material costs.

Thermal Barrier Coating (TBC): Applying a TBC helps protect the superalloy from extreme heat exposure, extending the life of downhole components used in geothermal and oil and gas applications.

Rapid Prototyping and Verification of Downhole Drilling Superalloy Assemblies

The rapid prototyping of downhole drilling assemblies accelerates the design-to-production cycle and allows for early identification of potential issues.

Rapid Prototyping Process

Superalloy 3D printing using technologies like SLM enables rapid prototyping of complex components. Coupled with CNC machining, prototypes can be produced quickly to validate design concepts.

Importance of Verifying Samples

Verifying prototypes is essential to ensure that the parts meet the necessary specifications. Physical testing of prototypes helps confirm material integrity, design accuracy, and compatibility with other components. Before moving forward with large-scale production, this step is crucial, especially for parts intended for downhole environments where reliability is critical.

Rapid prototyping combined with thorough verification minimizes risks and ensures the success of downhole drilling components in their intended applications.

Five Common FAQs About Downhole Drilling Superalloy Assemblies Manufacturing

Why are superalloys ideal for downhole drilling assemblies? Superalloys are used because of their exceptional resistance to high temperatures, corrosion, and mechanical stress. These properties are essential for downhole applications, which involve harsh environmental conditions.

What are the key benefits of using CNC machining in manufacturing superalloy assemblies? CNC machining offers precision and consistency, enabling the creation of intricate designs with tight tolerances. This precision ensures compatibility and reliability in downhole tools that face harsh mechanical stress.

How does HIP improve the quality of downhole drilling components? HIP eliminates internal voids and porosities, improving components' overall mechanical integrity and durability, which is crucial in high-pressure environments.

What are the typical quality control measures for downhole drilling assemblies? Quality control includes non-destructive testing (e.g., ultrasonic and X-ray), mechanical testing, chemical composition verification, and microscopic analysis. These measures ensure the reliability of components under demanding conditions.

How does rapid prototyping shorten the development cycle for these components? Rapid prototyping allows for quick production of components to validate designs. Using technologies like SLM and CNC machining, prototypes can be made and tested early in the development process, allowing for fast iteration and reducing the overall timeline for product development.