Applications of Unstructured Mesh and Finite Volume Methods in Superalloy Parts Manufacturing?

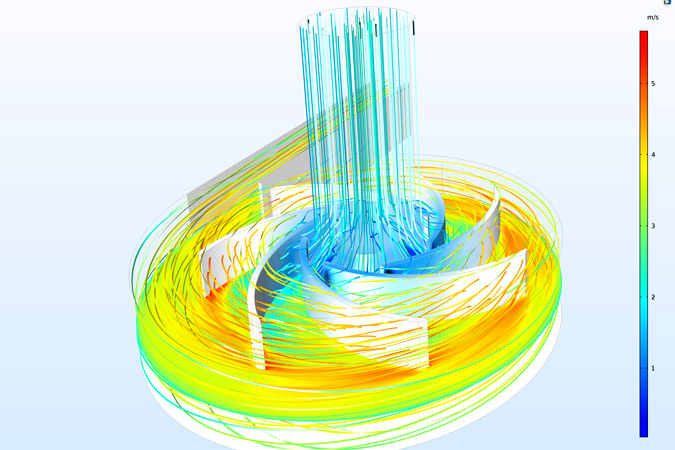

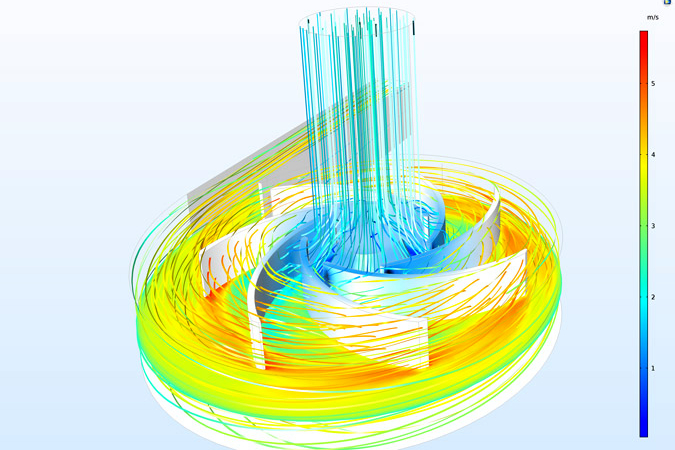

Manufacturing superalloy parts, which are essential for industries such as aerospace, energy, and power generation, involves complex processes requiring advanced simulation techniques to ensure high performance and precision. Unstructured mesh and finite volume methods (FVM) are computational techniques used to simulate fluid dynamics, thermal properties, and mechanical behavior in these materials, which are crucial in superalloy casting, forging, machining, and 3D printing. These methods are instrumental in processes like vacuum investment casting, single crystal casting, equiaxed crystal casting, directional casting, powder metallurgy, forging, CNC machining, and 3D printing. Creating detailed digital models of the superalloy components, unstructured mesh, and FVM allow engineers to optimize the design and performance of parts before they are physically manufactured. This leads to better control over the material's microstructure, temperature distribution, stress concentrations, and overall integrity, vital for high-performance components in the aerospace, power generation, and marine industries.

Overview of Superalloy Parts and Processes Requiring CFD Analysis

In superalloy manufacturing, a wide range of processes benefit from CFD analysis. The precision required for these processes and the necessity of defect-free components make CFD a crucial step. Vacuum Investment Casting relies on CFD to simulate uniform mold filling, preventing issues like porosity and ensuring consistent part quality. Single Crystal Casting uses CFD to manage the directional solidification required to form single crystals without grain boundaries.

Equiaxed Crystal Casting benefits from CFD simulations that help control cooling rates, resulting in uniform grain structures. Directional Casting also utilizes CFD to control thermal gradients and optimize the solidification process for improved mechanical properties.

Powder Metallurgy Turbine Discs involve CFD to analyze powder flow during compaction and sintering, ensuring homogeneous properties in the final product. Forging processes, including isothermal and precision forging, use CFD to predict material flow and minimize forging defects.

In CNC Machining, CFD helps optimize coolant flow, ensuring consistent tool life and preventing heat-induced defects in superalloy components. Finally, 3D Printing of Superalloys (Additive Manufacturing) leverages CFD to ensure uniform material deposition and eliminate weak areas or voids during printing, leading to more vital parts with fewer internal flaws.

Benefits to Different Superalloys

Unstructured mesh and finite volume methods provide distinct advantages for various superalloys with unique thermal and mechanical properties. Superalloys such as Inconel, CMSX, and Rene alloys benefit greatly from these computational methods, as they allow engineers to predict how these materials will behave under extreme conditions like high temperatures and stress.

For instance, Inconel alloys, known for their resistance to oxidation and high-temperature strength, are often used in turbine blades and exhaust systems. Using unstructured mesh for simulating heat distribution during casting processes can help ensure the alloy's structure remains uniform and free from defects such as hot spots or cracks.

Similarly, single crystal casting of CMSX alloys, used in high-performance turbine blades, requires precise thermal management and cooling simulations to avoid material defects. Using Finite Volume Methods (FVM) in such processes helps optimize the cooling rates, ensuring high-quality, defect-free components.

Meanwhile, the benefits of these methods extend to alloys like Hastelloy and Stellite, which are used in corrosion-resistant applications, ensuring optimal material properties during manufacturing.

Post-Processes Comparison

Post-processing is essential in superalloy part manufacturing to enhance the properties of the parts and ensure they meet stringent industry standards. Techniques like Hot Isostatic Pressing (HIP), heat treatment, and superalloy welding play vital roles in refining the microstructure and improving the overall mechanical properties of the parts.

Hot Isostatic Pressing (HIP)

HIP is commonly used after casting or additive manufacturing to eliminate internal voids and improve the material's density. For parts made through powder metallurgy or 3D printing, HIP can significantly improve the quality of the final product by eliminating residual porosity.

Heat Treatment

Heat treatment is employed to modify the mechanical properties of the alloy by altering its microstructure through controlled heating and cooling processes. This process is critical for achieving the desired balance of hardness, toughness, and strength in superalloys like Inconel and Nimonic.

Superalloy Welding

Superalloy welding is often used in repair or joining applications, especially for complex turbine components, ensuring the welded joints maintain the same high strength and thermal resistance as the base material.

Thermal Barrier Coatings (TBCs)

Lastly, thermal barrier coatings (TBCs) can be applied to parts exposed to extreme thermal cycles to improve their resistance to thermal fatigue.

The combination of these post-processing techniques can result in superalloy components that meet the stringent requirements for high-performance applications, such as in gas turbines and jet engines.

Testing

Testing is critical to superalloy manufacturing, ensuring that the final parts meet the required performance standards. Advanced inspection methods, such as Coordinate Measuring Machine (CMM) testing, X-ray, and scanning electron microscopy (SEM), are essential for verifying superalloy parts' dimensions, internal structure, and material properties. These tests help detect defects that may not be visible to the naked eye, such as cracks, porosity, or inclusions that could compromise the part's strength or performance.

Additionally, tensile testing and fatigue testing provide valuable data on the mechanical properties of the alloys, allowing manufacturers to assess the durability and strength of the parts under real-world conditions. These mechanical tests ensure that components can withstand operational stresses, such as the cyclic loads experienced in turbines or engines.

The integration of CFD (Computational Fluid Dynamics) analysis and unstructured mesh simulation further aids in understanding the behavior of superalloys in specific applications, such as fluid flow in turbine blades or heat dissipation in reactor vessel components. CFD simulations complement physical tests by predicting stress points and heat distribution, enabling manufacturers to optimize designs and performance.

Industry and Application

The applications of superalloy parts span numerous industries, each with unique performance requirements.

Aerospace and Aviation

In the Aerospace and Aviation sectors, superalloys like Inconel and CMSX are critical for components that operate under extreme temperature and stress conditions, such as turbine blades, exhaust systems, and heat exchangers. These materials ensure that parts maintain their integrity at high temperatures, reducing the risk of failure in jet engines and gas turbines. Superalloy jet engine components are a prime example of where these materials are employed to achieve maximum performance under harsh conditions.

Power Generation

In the Power Generation industry, superalloy parts are used in components like turbine blades and reactor vessel components, where resistance to thermal cycling and high-stress environments is essential for maintaining long-term performance and safety. Superalloys are indispensable for ensuring efficiency and reliability in gas and steam turbines, where they provide superior thermal stability and resistance to mechanical stresses over long periods of operation.

Oil and Gas

The Oil and Gas sector also benefits from superalloys, with components like corrosion-resistant pump systems and mixing system components being vital for the efficient extraction and transportation of resources. These components' high strength and corrosion resistance ensure that they can withstand the harsh environments of oil fields and drilling platforms, which are characterized by extreme pressures and aggressive chemical conditions.

Automotive and Marine

In the Automotive and Marine industries, superalloys are used in components like brake systems, transmission assemblies, and armor system parts, where strength, durability, and resistance to extreme conditions are paramount. These applications benefit from the exceptional mechanical properties of superalloys, which provide high performance, especially in high-stress environments, thereby ensuring the safety and reliability of vehicles and marine vessels in demanding operational scenarios.

FAQs

How do unstructured mesh and finite volume methods contribute to superalloy casting simulations?

What benefits do FVM and unstructured mesh bring to heat treatment processes?

Why are single crystal superalloys particularly suited to directional casting?

How do CFD and FVM work together in modeling aerospace components?

What challenges do unstructured mesh methods address in the forging of superalloys?