Aerospace-Grade Metal Heat Exchanger Units Manufacturing Hub

Brief Introduction of Heat Exchanger Units

A heat exchanger is a system used to transfer heat between two or more fluids without mixing them. This heat transfer can either cool or heat a fluid depending on the temperature difference between the fluids. In industrial applications, heat exchangers are essential for improving energy efficiency by utilizing the thermal energy from one fluid to heat or cool another.

For instance, in power plants, heat exchangers manage heat exchange between steam, water, or gases, whereas in HVAC systems, they regulate indoor air temperature. Heat exchangers manage engine temperatures in aerospace applications subject to extreme heat and pressure.

Heat exchangers' valves control the fluid flow to optimize this heat transfer, ensuring that the systems perform at peak efficiency. These valves need to be exceptionally durable and resistant to thermal fatigue, corrosion, and oxidation due to the harsh operational environments they face. Superalloy corrosion-resistant valve assemblies are the ideal solution for ensuring the reliability of heat exchanger units in these high-demand sectors.

Superalloys Used in Heat Exchanger Units

Superalloys are high-performance alloys that withstand extreme conditions, such as high temperatures, corrosion, and mechanical stress. These materials comprise nickel, cobalt, or iron, with other elements added to enhance specific properties. For heat exchangers, superalloys are necessary because they can perform reliably in high-temperature environments where traditional materials would fail.

The three most common types of superalloys used in heat exchangers include nickel-based alloys, cobalt-based alloys, and titanium-based alloys:

Nickel-based alloys

Nickel-based alloys like Inconel 718, Inconel 625, and Hastelloy X are widely used in heat exchanger systems. These alloys are known for their excellent resistance to oxidation, corrosion, and creep at high temperatures. Inconel 718, for example, has high strength and is commonly used in heat exchangers exposed to high-temperature steam, gas, or other aggressive environments. On the other hand, Hastelloy X is highly resistant to oxidation and sulfur-induced corrosion, making it ideal for heat exchangers in chemical processing plants.

Cobalt-based alloys

Cobalt-based superalloys such as Stellite are often used for components that experience extreme mechanical stress and wear. These alloys offer excellent wear resistance and are highly effective in applications that involve frequent contact between moving parts. Cobalt-based alloys are ideal for valve components exposed to high-velocity fluids or gases that could cause erosion or degradation of lesser materials.

Titanium-based alloys

Titanium alloys, especially Ti-6Al-4V, offer an exceptional strength-to-weight ratio, making them ideal for aerospace heat exchangers, where weight is critical. They also exhibit excellent corrosion resistance, even in aggressive environments like seawater or acidic chemicals. Titanium alloys are often chosen for lightweight but highly durable applications.

Heat Exchanger Units Manufacturing Process

The manufacturing process for heat exchanger units involves a combination of casting, forging, machining, and post-processing. The choice of manufacturing method depends on the material's properties, the complexity of the part, and the performance requirements.

Precision and material integrity are paramount for superalloy valve assemblies used in heat exchangers. Several advanced manufacturing methods are employed to produce high-quality components:

Vacuum Investment Casting

Vacuum investment casting is a precise method for creating complex superalloy valve assemblies. The process involves creating a ceramic shell around a wax pattern, which is then melted away, leaving a hollow mold. Superalloy material is poured into the mold under a vacuum to ensure the casting is free of air pockets and impurities, resulting in a high-quality, defect-free part.

One of the key advantages of vacuum investment casting is its ability to produce parts with fine details and complex geometries. This method is beneficial for manufacturing components like valve bodies, stems, and other intricate parts used in heat exchangers; by ensuring that the parts are free from defects like porosity and inclusions, vacuum investment casting guarantees superior performance and longevity for heat exchanger units.

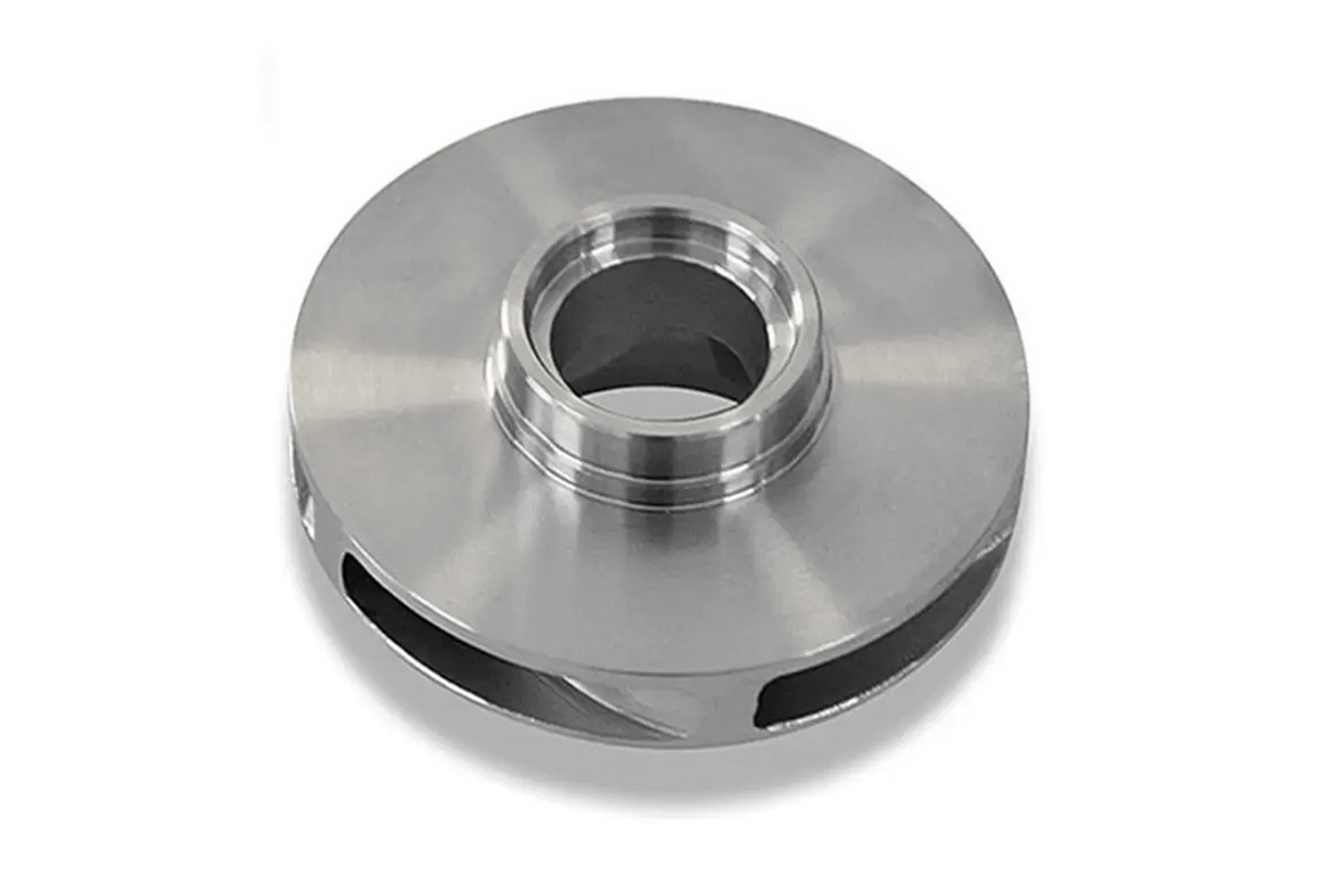

Superalloy CNC Machining

CNC (Computer Numerical Control) machining is essential for achieving tight tolerances and fine surface finishes in superalloy components. Superalloy CNC machining shapes and sizes the parts precisely after casting or forging. CNC machines, controlled by sophisticated software, can achieve the high precision and intricate shapes required for valve assemblies in heat exchangers.

CNC machining is critical when manufacturing components that meet strict dimensional requirements and have excellent surface quality. This process is often used for valve stems, seats, and other components where small tolerances and a smooth finish are necessary to ensure proper sealing and fluid flow in heat exchangers.

Superalloy Additive Manufacturing

Additive manufacturing (AM) technologies, such as Selective Laser Melting (SLM) and Wire and Arc Additive Manufacturing (WAAM), are revolutionizing the production of heat exchanger valve assemblies. SLM uses a laser to melt layers of powder, fusing them to create the final part. WAAM, on the other hand, uses a welding wire fed into an arc to melt the material and build it up layer by layer.

The primary advantage of additive manufacturing is its ability to produce parts with complex geometries and internal structures that would be difficult, if not impossible, to create with traditional casting or machining techniques. For heat exchanger valve assemblies, this technology enables the creation of custom geometries that optimize fluid flow, reduce weight, and enhance performance while maintaining the durability required in harsh environments.

SLM, in particular, allows for the precise manufacturing of superalloy valve components like Inconel 718, Hastelloy X, and Ti-6Al-4V. These materials exhibit excellent resistance to corrosion and high temperatures, making them perfect for heat exchanger applications. With additive manufacturing, companies can produce prototypes quickly and cost-effectively, accelerating product development and reducing time to market.

Heat Exchanger Units Quality Assurance

Quality assurance (QA) is essential throughout the manufacturing process to ensure the reliability and performance of superalloy corrosion-resistant valve assemblies. Each component is rigorously tested to meet industry standards and customer specifications.

The composition and properties of the superalloy material are tested to ensure they meet the required mechanical and chemical specifications. Chemical composition analysis is carried out to verify the alloy's strength, resistance to corrosion, and other vital properties. Tests such as tensile strength, hardness, and fatigue resistance ensure the material can withstand the high pressures and temperatures encountered in heat exchanger systems.

Dimensional and Surface Inspection

Since valve assemblies often require tight tolerances for proper fitting, dimensional checks are performed using coordinate measuring machines (CMM) or laser scanning. These tools ensure that each part meets the design specifications, such as size, shape, and surface finish. Surface inspections using techniques like dye penetrant testing and X-ray inspection detect surface and internal defects, such as cracks or voids, which could impact the functionality or safety of the valve assemblies.

Non-destructive testing (NDT) methods detect internal flaws that might not be visible to the naked eye. Standard NDT methods for superalloy components include ultrasonic testing, X-ray inspection, and eddy current testing. These techniques help ensure the parts are free from defects that could cause failures, especially under high-pressure, high-temperature conditions.

Thermal and Performance Testing

Superalloy valve assemblies undergo thermal cycling tests to simulate the harsh conditions the components will face during operation. These tests assess how well the materials hold up under temperature variations and thermal stress. Other performance tests assess valve functionality, such as pressure testing, to ensure the valve assemblies can handle the required fluid and gas pressures in the heat exchanger systems.

Heat Exchanger Units Industries and Applications

Superalloy corrosion-resistant valve assemblies are used across various industries where heat exchangers are integral to operations. Some of the critical industries and applications include:

Aerospace and Aviation

In aerospace, heat exchangers are crucial in engine cooling, environmental control, and fuel cooling systems. The valve assemblies used in these systems must withstand extreme temperatures and pressures, making superalloys essential. Materials like Inconel 718 and Hastelloy X are commonly used for these critical components.

Power Generation

In power plants, heat exchangers are used in systems like steam condensers, cooling towers, and geothermal heat exchangers. These units manage the heat produced during power generation and help optimize efficiency. Superalloy valves are used in high-pressure, high-temperature applications to control the flow of fluids while resisting corrosion from chemicals or high levels of salinity.

Oil and Gas

The oil and gas industry often uses heat exchangers in offshore drilling rigs, refineries, and petrochemical plants. The valve assemblies in these applications must resist high temperatures and corrosive fluids and gases, such as sour gas or brine. Superalloys like Inconel 625 and Hastelloy C-276 are commonly used in these environments.

Chemical Processing

Chemical plants often employ heat exchangers for reaction cooling, condensation, and solvent recovery. These systems require valves that can withstand highly acidic or basic fluids, making corrosion-resistant superalloys an essential choice for valve assemblies.

Marine and Nuclear

Heat exchangers are vital for managing heat in reactors and marine propulsion systems in marine and nuclear applications. Due to the harsh operating environments—such as seawater or nuclear reactor fluids—superalloy valve assemblies are required for longevity, reliability, and performance under extreme conditions.

Heat Exchanger Units Rapid Prototyping

Rapid Prototyping Process: Superalloy 3D Printing and CNC Machining

Rapid prototyping is essential for testing designs, reducing lead times, and accelerating the product development cycle. Technologies like superalloy 3D printing and CNC machining allow manufacturers to produce prototypes for heat exchanger valve assemblies quickly. With 3D printing, manufacturers can rapidly create valve assembly prototypes and test complex geometries' performance before final production. It helps identify design flaws early and allows for fast iteration of the prototypes. Technologies like Selective Laser Melting (SLM) and Wire and Arc Additive Manufacturing (WAAM) are crucial to producing intricate and large components, respectively.

CNC machining is also used to refine prototypes and achieve precise dimensions and surface finishes. The ability to produce high-precision valve components that can withstand extreme temperatures and pressures is critical for the performance of heat exchanger units, especially when working with high-temperature superalloys like Inconel or Hastelloy.

Importance of Verifying Samples

Verifying samples before full-scale production ensures that prototypes meet the design specifications and can perform under real-world conditions. This process can identify material weaknesses, design flaws, or manufacturing defects early in development. For heat exchanger units, verification includes mechanical testing, dimensional inspection, and thermal testing to ensure the parts can withstand the stresses of high temperatures and corrosive fluids.

This testing also helps confirm that the design will perform efficiently, meeting heat transfer and pressure requirements. It reduces the risk of failure by ensuring that only high-quality, reliable components reach the final production stage. Heat treatment and non-destructive testing (NDT) methods can further enhance material properties and detect potential defects in the prototypes. These verification processes ensure that the final heat exchanger components are safe, efficient, and durable in the demanding environments they will operate in.

FAQs About Heat Exchanger Units Manufacturing

What superalloys are most commonly used for manufacturing heat exchanger valve assemblies?

How does vacuum investment casting improve the quality of heat exchanger components?

What is the role of CNC machining in producing superalloy valve assemblies?

How does 3D printing affect the manufacturing process for heat exchanger units?

What are the key post-processing techniques used to enhance the durability of valve assemblies in heat exchangers?