Achieving Defect-Free Bonds with HIP Diffusion Connection

Hot Isostatic Pressure (HIP) diffusion connection technology has become an indispensable process in manufacturing high-performance turbine components, particularly in industries such as aerospace, energy, and oil and gas. HIP is a critical method to eliminate internal defects and ensure the structural integrity of superalloy parts used in high-stress applications. By applying high temperature and pressure in a controlled environment, HIP effectively diffuses bond interfaces, producing dense, uniform, and defect-free components that meet the rigorous performance standards required in these industries. The HIP process is particularly effective for superalloy parts used in turbine blades, discs, and other high-performance engine components that must perform under extreme conditions.

Superalloy Parts Requiring HIP Diffusion Connection

HIP diffusion connection is commonly applied to a wide range of superalloy parts, particularly those that undergo complex manufacturing processes such as casting, forging, or 3D printing. Each process creates unique challenges, often resulting in internal porosity, microvoids, and other defects that can compromise the material's performance.

Vacuum Investment Casting: This casting process produces intricate and complex geometries, such as turbine blades and discs. However, it often results in small internal voids that can affect the component’s mechanical properties. HIP eliminates these defects, ensuring a strong, uniform material structure that meets the required standards for high-temperature and high-pressure environments.

Single Crystal Casting: Single crystal castings are used in high-performance turbine blades and other aerospace components. This casting process requires careful control of the crystallization process to maintain the desired grain structure. HIP is crucial for removing any internal defects that could undermine the component’s strength, ensuring that the single crystal structure remains intact and performs optimally under extreme operational conditions.

Equiaxed Crystal Casting: In this casting method, the material is cooled so that the crystals form in a more uniform pattern. While this results in excellent material properties, it can still leave internal voids. HIP helps to remove these voids and homogenize the material, enhancing the mechanical properties of the casting, including its strength and resistance to fatigue.

Directional Casting: Directional casting is often used for turbine components that need to withstand intense thermal gradients. HIP is used to improve the bond integrity between the directional cast structures, ensuring no internal defects could cause failure under operational stresses.

Powder Metallurgy: In the powder metallurgy process, metal powders are compressed and sintered to form the final part. While this method offers high precision and uniformity in material properties, it can result in porosity and other internal defects. HIP is essential in powder metallurgy to enhance the sintering process, removing residual porosity and improving the material's mechanical properties.

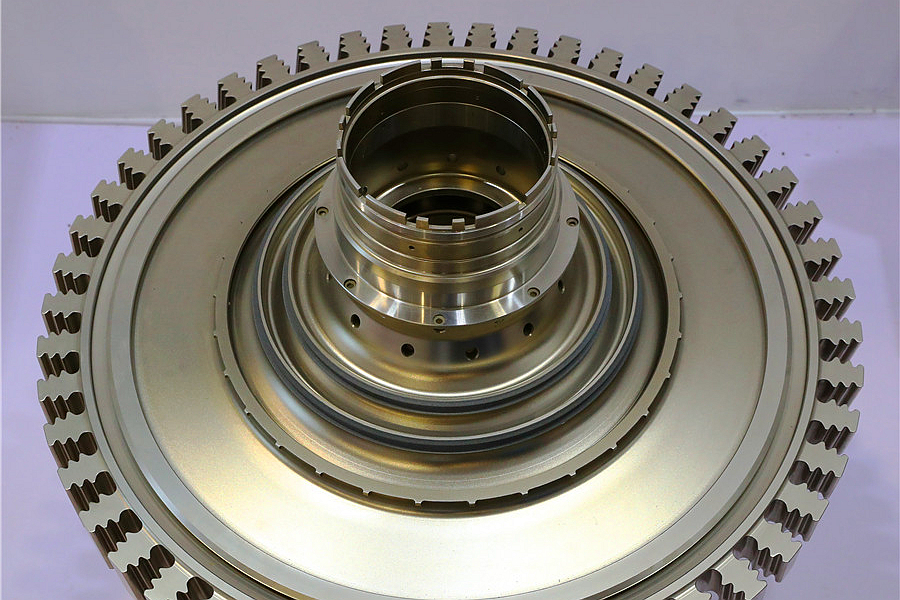

Forging: Forging shapes superalloy parts, such as turbine discs and blades, into their final forms. Internal defects can form during forging due to the stresses and temperature fluctuations involved. HIP ensures these defects are eliminated, creating dense, uniform parts that can withstand the high stresses of turbines and other critical components.

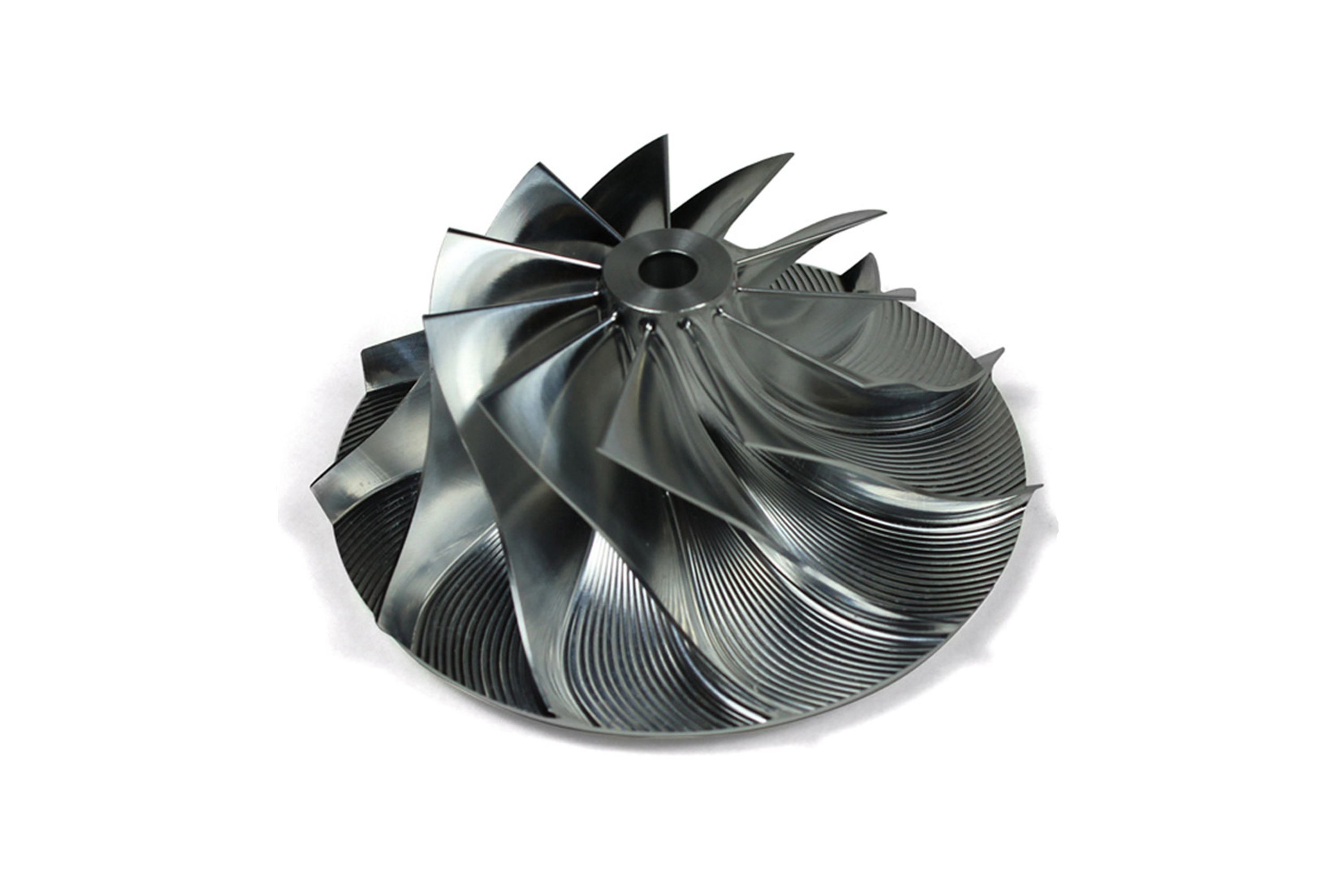

CNC Machined Parts: Parts that undergo CNC machining, particularly those with complex geometries, can suffer from internal voids or surface defects after the machining process. HIP is used as a post-process to eliminate these defects, and the final part is free from porosity and other weaknesses.

3D Printed Parts: Additive manufacturing techniques like 3D printing are increasingly used to produce complex, customized turbine components. However, 3D-printed parts often contain internal voids due to the layer-by-layer deposition process. HIP plays a critical role in removing these defects, ensuring that the printed parts have the required mechanical properties and can perform under the high stresses encountered in aerospace and energy applications.

Benefits to Different Superalloys

HIP diffusion connection offers significant benefits across various superalloys, ensuring that they meet the rigorous performance standards required in aerospace, energy, and other high-stress industries.

Inconel Alloys

Inconel alloys, such as Inconel 718 and Inconel 625, are widely used in high-temperature applications, including gas turbine engines and jet engines. HIP helps eliminate porosity and improve the alloy’s overall mechanical properties, including its oxidation and thermal stability resistance. This is especially critical in aerospace applications where components are exposed to extreme temperature gradients and high mechanical loads.

CMSX Series

The CMSX series of superalloys, including CMSX-4 and CMSX-10, are commonly used in single-crystal turbine blades and other high-performance aerospace components. HIP ensures that these alloys remain defect-free, helping to preserve the integrity of the single-crystal structure, which is essential for the alloys' high creep resistance and long-term performance at elevated temperatures.

Rene Alloys

Rene alloys, such as Rene 41 and Rene 104, are used in turbine blades and combustion chambers for high-performance engines. These alloys benefit from HIP in removing any internal defects that could weaken the material's ability to withstand high thermal and mechanical stresses, improving their resistance to creep and fatigue under extreme conditions.

Titanium Alloys

Titanium alloys, including Ti-6Al-4V, are used in aerospace applications for components that require a high strength-to-weight ratio. HIP helps remove any internal voids or defects that could compromise the material’s performance, ensuring that the titanium components are both lightweight and strong enough to meet the demands of modern aerospace engineering.

Monel and Hastelloy Alloys

Monel alloys and Hastelloy alloys are known for their exceptional corrosion resistance, making them ideal for marine, chemical processing, and other high-corrosion environments. HIP ensures these alloys are free from internal porosity, critical for maintaining their durability and strength in harsh chemical or marine environments.

Post-Processes Comparison

While HIP is a powerful tool for eliminating internal defects and improving material integrity, it is often used with other post-processing techniques to optimize the performance of superalloy parts.

Heat treatment vs. HIP: Heat treatment is commonly used to alter the microstructure of superalloys, enhancing their strength, hardness, and resistance to fatigue. However, heat treatment cannot eliminate internal defects such as porosity, where HIP is critical. HIP works in tandem with heat treatment to improve the material’s microstructure and ensure that it is free from internal flaws that could compromise its performance under high-stress conditions.

Welding vs. HIP: Welding is another process used to join components, but it can introduce residual stresses and defects, especially in high-temperature alloys. In contrast, HIP provides a more uniform bond, ensuring the final product is free from internal defects often occurring in welded joints. HIP diffusion bonding benefits high-performance applications with critical bond integrity, such as in turbine discs and blades.

Thermal barrier coatings (TBC): Thermal barrier coatings are often applied to turbine blades and other high-temperature components to protect them from extreme heat. HIP ensures that the underlying material is dense and free from porosity, which helps ensure that the TBC adheres appropriately and performs as expected under high-temperature conditions.

CNC machining and HIP: CNC machining is used to achieve the precise geometries required for turbine components, but machining can also introduce defects or leave residual stresses. After machining, HIP removes these defects, leaving a dense, uniform material structure ideal for high-performance applications.

Testing of HIP Diffusion Bonded Components

The quality of components produced using HIP diffusion bonding technology is assessed through various testing methods to ensure the parts meet the required mechanical and performance standards.

Tensile Testing: Tensile testing assesses the strength of the HIP-bonded components, measuring their ability to withstand tensile forces without breaking or deforming. This is crucial for turbine components exposed to high mechanical loads during operation.

X-ray and Ultrasonic Testing: These non-destructive testing methods are used to inspect the internal structure of the bonded parts. X-ray and ultrasonic testing can detect residual porosity or internal voids that might compromise the part’s structural integrity, ensuring that the HIP process has effectively eliminated defects.

Metallographic Examination: Metallographic examination involves analyzing the microstructure of the HIP-bonded part to ensure that the bonding process has resulted in a uniform and defect-free material. This testing provides valuable insights into the quality of the bond and the overall material properties. For better evaluation, techniques such as EBSD analysis help assess grain boundaries and phase distribution.

Hardness Testing: Hardness testing is used to assess the overall hardness of the part after HIP, ensuring that it has the necessary resistance to wear and deformation under operational conditions.

Fatigue Testing: Fatigue testing evaluates how the bonded part performs under cyclic loading. This is particularly important for turbine components subjected to repeated stresses and thermal cycles during operation. Fatigue testing ensures that the HIP-bonded components will maintain their integrity over time, making them suitable for high-performance applications like turbines and aerospace components.

Industry and Application of HIP Diffusion Connection Technology

HIP diffusion connection technology is widely used in several industries that demand high-performance, defect-free materials. These industries rely on HIP to ensure the reliability and durability of critical components used in turbines, engines, and other high-stress applications.

Aerospace

HIP is extensively used in the aerospace industry to produce turbine blades, discs, and other high-performance components exposed to extreme temperatures and mechanical loads. HIP ensures these components are free from internal defects, essential for ensuring their long-term performance and safety in jet engines and gas turbines. Learn more about how HIP is applied in aerospace applications.

Power Generation

Gas and steam turbines used in power generation require components that can withstand high temperatures and pressures. HIP ensures that turbine discs, blades, and other critical components meet the stringent performance requirements for power generation. Discover more about HIP in power generation systems.

Oil and Gas

The oil and gas industry uses HIP to manufacture components that must endure extreme conditions, such as high pressure and corrosion. HIP ensures that parts used in offshore drilling rigs, pumps, and compressors are free from defects that could lead to failure in these challenging environments. Explore our HIP solutions for the oil and gas sector.

Marine

The marine industry relies on HIP for components such as turbine blades in naval ships and offshore platforms. HIP ensures that these parts are strong, durable, and able to withstand the harsh conditions found at sea. Learn more about HIP applications in marine environments.

Automotive

HIP technology also benefits from automotive applications, particularly in racing or high-performance engines. It ensures that components such as turbine blades and engine parts have the necessary mechanical properties and durability for demanding applications. Explore how HIP enhances high-performance automotive components.

Energy

The energy sector, including wind turbines and other renewable energy technologies, benefits from HIP to ensure the structural integrity of turbine components. HIP helps improve these components' strength and fatigue resistance, allowing for longer operational lifespans. Learn more about HIP applications in energy production.

Chemical and Pharmaceutical

HIP produces components for heat exchangers, reactors, and other critical components that must resist corrosion and maintain high performance under extreme conditions. These applications require materials free from defects and capable of handling challenging chemical environments. Discover HIP solutions for the chemical and pharmaceutical industries.

FAQs

How does HIP improve the performance of single crystal castings in turbine components?

What are the key differences between HIP and other post-processing techniques like heat treatment and welding?

How do different superalloys benefit from HIP in terms of structural integrity and performance?

What types of testing are performed on HIP diffusion-bonded turbine components?

Which industries rely most on HIP technology for manufacturing high-performance turbine parts?